- admin@vsolutionsind.com

- Sreepathy Nagar, Nanjundapuram PO, Coimbatore

- Customer Support: 82483 12074

Products

Refrigeration Units

Refrigeration units are essential systems designed to maintain low temperatures, preserving perishable goods, and ensuring optimal storage conditions for food, medicine, and other temperature-sensitive products.

Puff Panel

Puff panels, also known as insulated sandwich panels, are advanced building materials widely used in construction for their excellent thermal insulation properties and structural strength. These panels consist of two outer layers of durable material, such as steel or aluminum, and a core of insulating material, typically polyurethane foam or polystyrene.The primary advantage of puff panels is their high thermal insulation capability. The core material effectively reduces heat transfer, maintaining stable internal temperatures and significantly improving energy efficiency. This makes puff panels ideal for applications requiring strict temperature control, such as cold storage rooms, refrigerated warehouses, and food processing facilities.In

Deep Freezer

A deep freezer is a specialized appliance designed to store food and other perishable items at extremely low temperatures, typically around -18°C (0°F) or lower. These freezers are essential for households, restaurants, and commercial establishments, allowing long-term preservation of food products by significantly slowing down the growth of bacteria and the process of spoilage.Deep freezers come in two main types: upright and chest freezers. Upright freezers resemble conventional refrigerators, with vertical shelves that make it easy to organize and access items. Chest freezers, on the other hand, have a horizontal design, providing more storage space and better energy efficiency due

Cold Storage

Cold storage facilities are crucial in preserving the quality and extending the shelf life of perishable goods. These facilities are used across various industries, including agriculture, food and beverage, pharmaceuticals, and biotechnology, to store products at controlled temperatures.Cold storage solutions range from small, walk-in coolers to large, warehouse-sized cold rooms. They are designed to maintain specific temperature ranges to suit different types of products. For instance, fresh produce, dairy, and meat are typically stored at temperatures between 32°F and 41°F (0°C to 5°C), while frozen goods require temperatures well below freezing, often around -10°F to -20°F (-23°C to -29°C).The primary

Walk-in Chiller

A walk-in chiller is a large, refrigerated room used for storing perishable goods at a consistent, cool temperature. Commonly found in restaurants, supermarkets, and food processing facilities, walk-in chillers are essential for preserving the freshness and quality of food items, preventing spoilage, and extending shelf life.The design of a walk-in chiller includes insulated walls, floors, and ceilings to maintain the desired internal temperature. The refrigeration system typically consists of an evaporator, condenser, and compressor, working together to remove heat from the interior and keep the space cool. The temperature inside a walk-in chiller is usually set between 32°F and 41°F

Industrial Chillers

Industrial chillers are essential components in various manufacturing processes, providing precise temperature control to ensure the efficient and safe operation of equipment and processes. They are used across multiple industries, including plastics, food and beverage, pharmaceuticals, and chemical processing.The primary function of industrial chillers is to remove heat from a process or equipment. This is achieved through a refrigeration cycle that involves the absorption of heat from the process fluid and its transfer to a cooling medium, typically water or air. The chilled fluid is then recirculated through the system to maintain the desired temperature.Industrial chillers are available in several

Air Handling Unit

An Air Handling Unit (AHU) is a vital component of HVAC (Heating, Ventilation, and Air Conditioning) systems, designed to regulate and circulate air within a building. AHUs are commonly used in commercial, industrial, and large residential buildings to ensure a comfortable and healthy indoor environment.An AHU typically consists of several key components, including filters, fans, heating and cooling coils, humidifiers, and dampers. These components work together to perform various functions such as filtering the air, controlling temperature and humidity, and distributing the conditioned air throughout the building via ductwork.One of the primary functions of an AHU is to filter the

Ventilation Fans

Ventilation fans play a crucial role in maintaining indoor air quality by removing stale air, moisture, and pollutants from various spaces. These fans are essential in both residential and commercial settings, ensuring a healthy and comfortable environment.There are several types of ventilation fans, each designed for specific applications. The most common types include exhaust fans, ceiling fans, inline fans, and wall-mounted fans. Exhaust fans are typically installed in bathrooms and kitchens to expel moisture, odors, and fumes, preventing mold growth and maintaining a fresh atmosphere. Ceiling fans circulate air within a room, providing a cooling effect and enhancing the efficiency

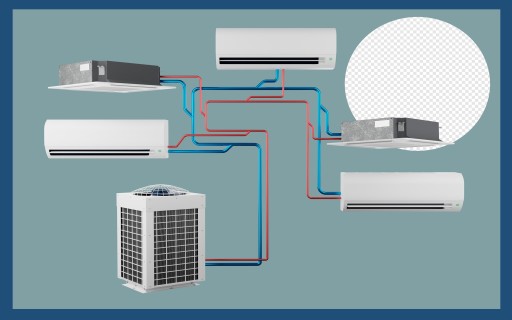

VRF/ VRV Systems

Variable Refrigerant Flow (VRF) and Variable Refrigerant Volume (VRV) systems are advanced air conditioning solutions designed for optimal efficiency and flexibility in managing the indoor climate of both residential and commercial buildings. These systems use refrigerant as the cooling and heating medium, allowing for precise temperature control across multiple zones within a building.The primary advantage of VRF/VRV systems lies in their ability to simultaneously cool and heat different areas of a building. This is achieved through a sophisticated network of indoor units connected to a single outdoor unit. Each indoor unit can operate independently, allowing for personalized climate control in